We are industry

leaders in Fabrication

Over 40 years of experience

Speed & Quality are our priority

We’re Experts in Fabrication

At Laser Expertise we strive to offer the highest quality standards & fast turnarounds.

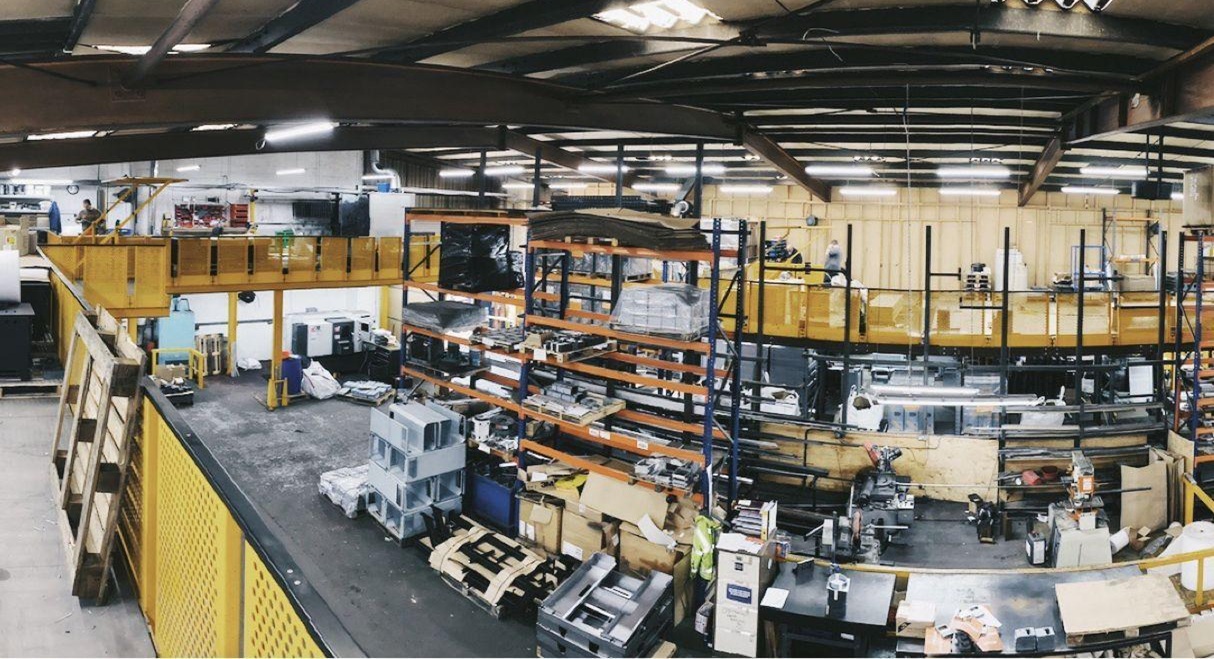

Our one-stop-shop service is trusted by global companies to provide them with all their fabrication requirements. Order complete assemblies & finished items without needing to source multiple suppliers – our 24hr operation and 65 staff are here to help.

What’s on the Production Line?

Who we are

Company

We’ve been in the industry for over 35 years, we’ve come a long way in that time and now offer more services than ever before.

Machinery

We regularly invest new machinery to ensure that you get the best quality products.

Featured Project

Quality laser cutting for a premium steel grill and fire table supplier